In order to make your tractor run to its full potential, it needs to be maintained on a regular basis. Regular Tractor maintenance servicing schedule avoids failure when using your machine, improves the fuel economy and increases the total amount of years of your tractor’s life.

At AgroAsia Tractors, a reliable and comprehensive guide on servicing of all models are offered to ensure farmers and operators remain productive all through the year.

The importance of regular tractor maintenance & servicing

- Timely maintenance minimizes the working idles and enhances efficiency. That is why regular checks are important

- Better Fuel Economies – Damaged filters and low levels of oil strain the engines and use more fuel.

- Long lasting life engine-Less wear and tear parts, lubricated, and well maintained.

- Lower Repair Bills – Early tractors repair and servicing of small problems reduce the final cost that can be incurred due to any breakdown.

- Superior Safety the lights, brakes, and steering can be evaluated regularly providing safety to the operators.

- Higher resale value A well maintained tractor has better resale value.

Checklist of Tractor Maintenance & Servicing Schedule

- Daily Daily visual, checking fluids, and leakage detection

- Weekly (40 50 hrs) Engine oil, greasing points and filters

- Monthly (100 hrs) Full fluid oil top up, belts, air system

- Seasonal overall inspection prior to planting/aking

- Yearly Full service, change of oil, overhaul

Engine & Fluid System

- Engine oil level [Check]: Check the level and add the recommended oil as specified by the manufacturer using dipstick.

- Radiator Coolant Level [Check]: Make sure that radiator has proper mixture of coolant-water to avoid overheating.

- Check Hydraulic Oil: Check the levels to make the hydraulic lift system operate smoothly.

- Transmission Oil [Check]: Clean and replace when filthy or at sub-optimal levels to keep the gear working.

- Check Brake (Hydraulic) Oil Level: Keep the brake fluid up to ensure responsive braking.

- Oil Level in Steering Pump: Steering oil enables responsive control — add some when necessary.

- Check All Gauges and Warning Lights: Check temperature, oil pressure, and fuel gauges.

Belts, Filters & Greasing Places

- Tension and Wear of Fan Belt: Overheating and power loss may occur due to a loose or cracked belt.

- Grease Universal Joints: Apply grease to avoid friction and mechanical failure.

- Steering Pivot Pin: Ensures smooth steering response and minimizes wear.

- Grease Front Axle Unit: Shields against wear in rough or heavy hardware conditions.

- Grease All Greasing Nipples (Zerks): Lubricate all zerk points to protect moving parts.

Air In-take System

- Clean Pre-Air Cleaner Glass Bowl: Remove dust and debris that may block air supply to the engine.

- Clean & Change Air Filter: Replace clogged filters to maintain performance and fuel efficiency.

Structural and Miscellaneous – Tractor Maintenance

- Oil and Fluid Leak: Check under the tractor and around the engine for any oil leak or fluid drips. A common issue in farm tractor maintenance, early detection can prevent costly repairs.

- Screw Nuts and Bolts: Tighten all screws, nuts, and bolts regularly, especially in high vibration areas like the chassis and steering assembly. This is a vital step in any routine tractor servicing.

- Oil Steering Assembly: Lubricate to prevent seizure. Proper steering assembly maintenance ensures safe handling and extends component life.

Tractor Maintenance Tips – How to Service a Tractor

- Store Under Cover: Reduce the risk of rust and weather-related damage by parking your tractor under a shed. It’s a basic but important tractor maintenance tip.

- Keep a Service Logbook: Track all tractor service intervals, part replacements, and inspections. This helps in planning regular tractor maintenance schedules.

- Manufacturer-Recommended Oils and Grease: Always use OEM-specified lubricants to maintain tractor performance and protect internal parts.

- Conduct a Light Visual Scan Before Each Use: A quick daily tractor inspection helps detect issues like oil leaks, loose parts, or worn belts before they become critical.

- Keep Safety Equipment Ready: Always have a fire extinguisher and a first-aid kit with you while operating machinery. Tractor safety tips are essential for every operator.

Conclusion – Keep Your Tractor in Top Shape

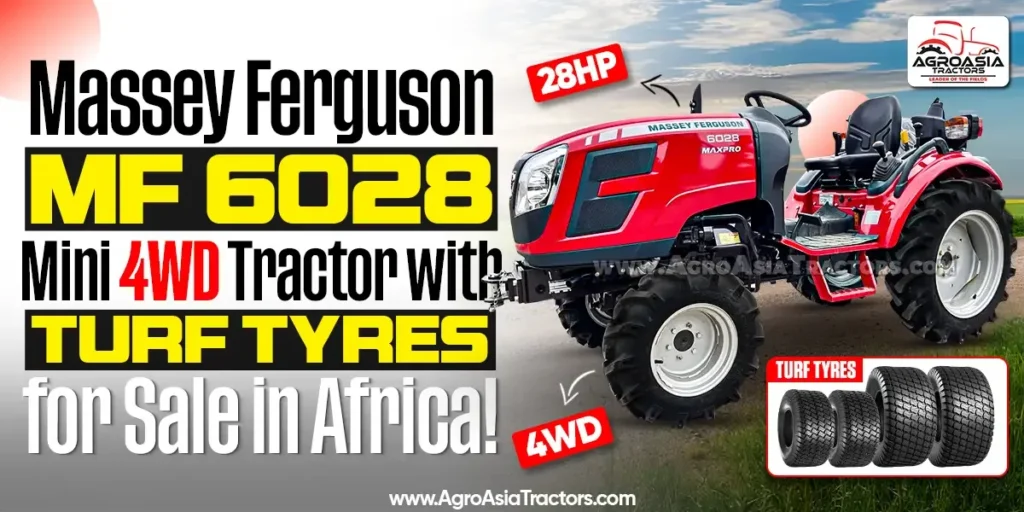

A consistent tractor maintenance timetable ensures power, safety, and peak efficiency across all your farming operations. Whether you own a Massey Ferguson tractor, a New Holland tractor, or a reliable John Deere models, regular servicing is the backbone of performance and longevity.

The comprehensive tractor servicing checklist provided by AgroAsia Tractors is designed to maintain your machine’s health season after season. From daily inspections to full fluid checks, our plan supports optimal farm tractor performance for every major brand.

Stay one step ahead of breakdowns. Invest in preventive tractor maintenance and protect your investment. Trust AgroAsia Tractors as your lifelong partner in agricultural success and equipment reliability.

Combo Packs – Brand New Tractors with Implements

AgroAsia Tractors offers specially curated combo packs that combine a brand-new tractor with essential farm implements—giving you a complete, ready-to-use agricultural solution. These value-packed bundles may include disc ploughs, offset disc harrows, rotary tillers, trailers, and more. Whether you’re choosing a Massey Ferguson, New Holland, or John Deere tractor, our combo offers are designed to meet the practical needs of farmers across Africa, the Middle East, and beyond.

These tractor and implement combo deals are perfect for new farm setups, upgrading equipment, or expanding your operations. They help reduce equipment downtime, lower overall costs, and ensure compatibility between tractor and tools. Contact AgroAsia Tractors today to explore the best package suited for your farming requirements.